The Hidden Backbone of Global Trade

Supply chains are the unsung heroes of modern economies. They are the invisible arteries through which goods and services flow across the globe, connecting producers, manufacturers, and consumers in a delicate balance. The goods we rely on every day—from food to electronics to essential machinery—are part of vast networks that span continents. Yet, these networks are not invincible. When disruptions occur, the effects ripple throughout the global economy, often in unexpected ways.

In recent years, supply chains have been under increasing pressure. From natural disasters and political instability to the COVID-19 pandemic, a range of factors has exposed the fragility of these systems. As disruptions occur, they send shockwaves that reverberate across industries, influencing everything from production costs to consumer prices. The growing vulnerability of supply chains has had significant effects on global markets, particularly on the prices of goods.

The Fragility of Global Supply Chains

Supply chains are inherently complex and interdependent. A single product can involve multiple suppliers from different parts of the world, each contributing a small piece to the final product. For example, a smartphone might be assembled in one country, using parts sourced from several others. These include raw materials, such as metals from Africa, microchips from East Asia, and assembly components from Europe. Each step relies on the previous one, and a disruption in one location can halt production in another.

The interconnectedness of modern supply chains is a double-edged sword. While they enable the efficient flow of goods and services, they also expose economies to a higher degree of risk. Disruptions in any part of the chain, whether from political turmoil, pandemics, natural disasters, or logistical bottlenecks, can cause cascading delays and shortages. The longer the disruption persists, the greater the strain on the supply chain and the higher the likelihood of price increases for both producers and consumers.

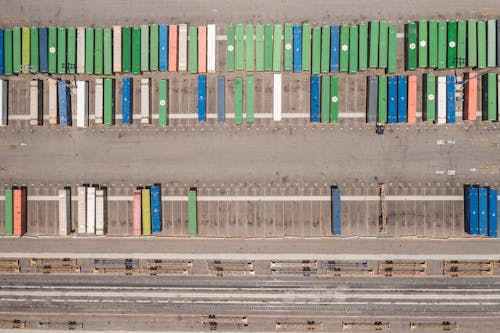

The Role of Transportation and Logistics

Transportation is one of the most vulnerable elements of the supply chain. The movement of goods relies heavily on shipping, air transport, and railways. Any disruption to these systems can cause significant delays. For example, the blockage of the Suez Canal in 2021 created a global bottleneck that delayed the delivery of goods worth billions of dollars. Similarly, disruptions to shipping routes due to port congestion or lack of available containers have slowed down the flow of goods worldwide.

As transportation costs increase, companies are forced to pass these costs onto consumers. The impact is especially visible in industries that rely on global shipping, such as electronics, automotive, and retail. Higher transportation costs can lead to increased prices for goods, contributing to inflationary pressures on a global scale.

Impact on Raw Materials and Commodities

Raw materials, such as oil, metals, and agricultural products, are another key component of supply chains. Prices for these materials are highly sensitive to disruptions. A shortage in one region can lead to price hikes that affect industries worldwide. For example, disruptions in the supply of steel or copper can have far-reaching consequences for construction, electronics, and automotive industries.

The COVID-19 pandemic had a dramatic effect on commodity markets, especially in the early stages of the crisis. As countries imposed lockdowns, the demand for raw materials plummeted. However, as economies began to recover, the demand for commodities surged, while supply chains were still reeling from the effects of the pandemic. This imbalance caused commodity prices to spike, adding pressure to the already strained global economy.

Similarly, agricultural products are subject to the whims of climate change. Droughts, floods, and extreme weather events can devastate crops, leading to shortages and price increases. The 2021 drought in Brazil, for example, contributed to a global rise in the price of coffee, soybeans, and sugar, while floods in Europe and Asia wreaked havoc on local farming.

Technology and Supply Chain Resilience

As supply chains face growing pressures, companies are turning to technology to help mitigate risks. Advances in automation, artificial intelligence, and data analytics are allowing businesses to better track inventory, predict disruptions, and optimize logistics.

Automation in manufacturing, for instance, reduces the reliance on human labor, which can be susceptible to labor shortages or strikes. AI can predict potential disruptions and suggest alternate suppliers or transportation routes, helping companies avoid costly delays. Additionally, blockchain technology has the potential to increase transparency and traceability within supply chains, ensuring that disruptions are identified quickly and remedied efficiently.

However, technology alone cannot eliminate the underlying vulnerabilities of global supply chains. For example, while automation may help streamline operations, it does not protect against external shocks, such as geopolitical tensions or environmental disasters. Businesses must balance the benefits of technological innovation with a greater understanding of the risks inherent in global supply networks.

Price Increases Across Sectors

The most immediate consequence of supply chain disruptions is the increase in prices for goods and services. When the flow of raw materials, components, or finished goods is interrupted, the cost of production rises. These increased costs are then passed on to consumers, who experience higher prices at the checkout.

For instance, the automotive industry has faced significant price hikes due to shortages of microchips, a crucial component in modern vehicles. As microchip production slowed during the pandemic, automakers struggled to source enough components for their vehicles. This led to production delays, fewer vehicles available for sale, and a surge in prices for both new and used cars.

Similarly, the food industry has been impacted by supply chain pressures, with rising costs for labor, transportation, and raw materials contributing to higher prices for groceries and dining out. Consumers have seen sharp increases in prices for staples such as meat, dairy, and grains, as well as processed foods. Even seemingly unrelated sectors, such as electronics and home goods, have been affected, as components like semiconductors are integral to the production of a wide range of products.

Long-Term Solutions and Future Outlook

To address the fragility of supply chains, many experts advocate for diversification and localization. Companies that rely heavily on single suppliers or regions may want to reconsider their strategies, spreading risk across a broader range of sources. Additionally, reshoring—bringing manufacturing back to home countries—could help reduce dependence on global supply chains and mitigate the impact of future disruptions.

However, these strategies come with trade-offs. Diversifying supply sources and reshoring production can increase costs and complicate logistics. Businesses must weigh these factors carefully, balancing resilience with profitability.

As we look ahead, supply chains will continue to be a critical factor in global economic stability. The pressures of climate change, geopolitical tensions, and evolving consumer demands will undoubtedly challenge these networks further. However, by investing in technology, improving transparency, and rethinking strategies, businesses can better withstand the shocks that are likely to come.

Conclusion

The fragility of global supply chains is a reality that cannot be ignored. From transportation bottlenecks to shortages of raw materials, the pressure on these networks is only growing. As disruptions continue to drive up prices, the effects are felt by consumers, businesses, and governments alike. Addressing the vulnerabilities in supply chains is crucial for maintaining economic stability in an increasingly complex and interconnected world. By learning from past disruptions and adapting to the challenges ahead, economies can build more resilient and sustainable supply chains for the future.